In a combined cycle gas turbine, the combustion of pressurized air with natural gas generates in the range of 700˚ C. This high pressure exhaust drives a series of turbine blades to generate electricity, and then is re-routed to generate steam that against drives a turbine to generate electricity. The CCGT releases large volumes of waste heat.

We plan to utilize 70˚ C. of this waste heat to evaporate sea water in a series of ‘effects’ or chambers. This evaporated water is collected, then pumped through a series of membranes to reduce ‘Total Dissolved Solids” in the water to 5 parts per million.

This water is considered to be ‘demineralized’ sufficiently to be used in the inlet fog cooling systems of our CCGT platforms without damaging the cooling or turbine subsystems.

We have determined that four 25,000 cubic-meter MED desalination trains can be powered from the exhaust of 200 MW of open cycle gas turbine system exhaust output. Thus, we calculate that the 322 MW CCGT platform can power four 25,000 cubic-meter MED desalination trains.

We will build five 322 MW CCGT platforms, therefore, we believe we can power twenty 25,000 cubic-meter MED desalination trains. We expect to produce 500,000 cubic meters of <5ppm TDS water per day from these trains.

Reliance-India-Project – 400,000 cubic meter case history

We plan to market water remaining after deducting the CCGT platforms’ requirements in two TDS quality levels. “High TDS levels (>500 mg / liter) results in excessive scaling in water pipes, water heaters, boilers, and household appliances, shorting their service life. …Water with extremely low concentrations of TDS may also be unacceptable because of its flat, insipid taste.”

[ https://www.who.int/water_sanitation_health/dwq/chemicals/tds.pdf ]

Excellent Quality is less than 300 mg / liter (<30ppm TDS) for high-value bottled water sales

Good Quality is between 300 and 500 mg / liter (30-50ppm TDS) for standard piped-water sales

50% of the water is removed from seawater, leaving 200% brine level water — some 500,000 cubic meters per day.

…what do you think would happen to Manda Bay when you send back 500,000 cubic meters of heavy brine every day into the sea?

No Pollution: We can’t NOT manage this brine.

Therefore, we will identify a variety of chemical beneficiation opportunities to take advantage of this brine and make money.

Example: Visualize a two meters-in-diameter pipe that is looped from the desalination trains through which the day’s brine output is passed through the night. The Oak Ridge National Lab’s amidoxime-doped polymeric fibers that draw Uranium atoms out of seawater are arrayed inside this 2 meter pipe loop. As there is an average of 3 milligrams of Uranium in each cubic meter of seawater, passing 500,000 cubic meters of 200% seawater brine across a fabric of such fibers can enable the collection of up to 50% of the daily out flow of brine’s 6 million milligrams [or ~3,000 grams]. At this rate, how much could this desalination beneficiation harvest per year? — about 1,095 kg. of Uranium…as an ancillary exploitation.

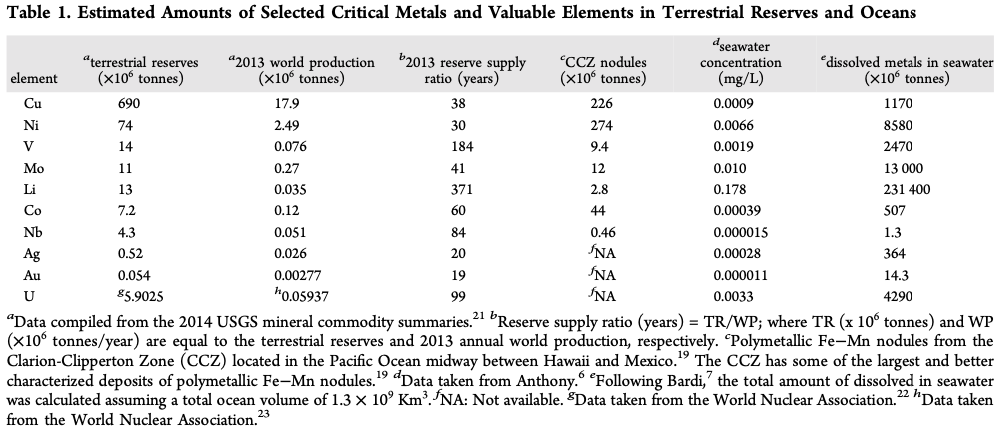

— only a PARTIAL list of critical elements available from seawater

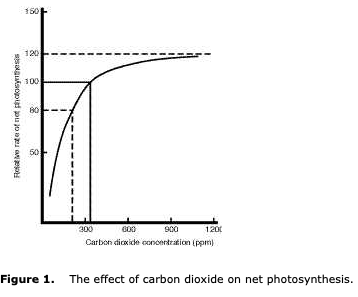

Without additional input of pure carbon dioxide, the carbon dioxide content of the atmosphere in the greenhouse can be reduced to less than 50 percent in some cases of its normal content in air. This shortage of carbon dioxide reduces the efficiency of photosynthesis and can have several negative effects on the health and development of greenhouse crops.

Carbon dioxide enrichment systems should be turned on during sunrise, and turned off several hours before sunset; however, additional carbon dioxide enrichment may be needed if supplemental lighting is used at night to insure adequate levels. In general, crop production times from late fall through early spring increases the potential need for carbon dioxide enrichment as it coincides with reduced ventilation rates due to colder outdoor air temperatures.

For most crops the saturation point for CO2 will be reached at about 1,000 ppm – 1,300 ppm. Increased CO2 levels shorten the growing period (5% – 10%), improve crop quality and yield as well as increase leaf size and leaf thickness. Increased yield in some crops results from the increased numbers and faster flowering per plant. To increase the level from 340 ppm to 1,300 ppm requires the addition of 1,000 ppm or 0.1% of CO2. This requires .40 cubic meters or .75 kg of CO2 per 100 square meters of greenhouse floor space. CO2 levels are reduced in a greenhouse by natural air exchange as well as photosynthesis. Once a level of 1,300 ppm is achieved it must be maintained. Photosynthesis normally occurs during daylight hours only, CO2 supplies are not depleted so much at night.

If we burn a cubic meter of natural gas this generates about 1.8 kg of CO2 and about 1.4 kg of water vapor. Ambient CO2 levels in the outside air is about 340 ppm by volume. Any actively growing crop in a tightly-clad greenhouse with little or no ventilation can readily reduce the CO2 level during the day to as low as 200 ppm. The decrease in photosynthesis when the CO2 level drops from 340 ppm to 200 ppm is similar to the increase in photosynthesis when the CO2 levels are raised from 340 ppm to about 1,300 ppm.